When using a replaceable open-end torque wrench, the appropriate torque should be selected based on the size of the bolt or nut that needs to be tightened or loosened. Next, install the torque wrench on the bolt or nut that needs to be tightened or loosened, and ensure that it is in close contact with the bolt or nut. If insufficient or excessive torque is found during operation, the output torque can be changed by adjusting the setting of the torque wrench. When applying torque, clockwise direction is tightening (increasing torque), counterclockwise direction is loosening (decreasing torque). Apply force evenly during the operation to avoid sudden increase in force that may cause damage to bolts or nuts. After reaching the required torque, it is necessary to check whether the bolts or nuts have been tightened or loosened to the appropriate degree. Finally, after completing the tightening or loosening task, it is necessary to remove the torque wrench from the bolt or nut. During the disassembly process, be careful not to apply too much force to avoid damaging the tool itself.

In addition, when using a replaceable open-end torque wrench, the following points should be noted:

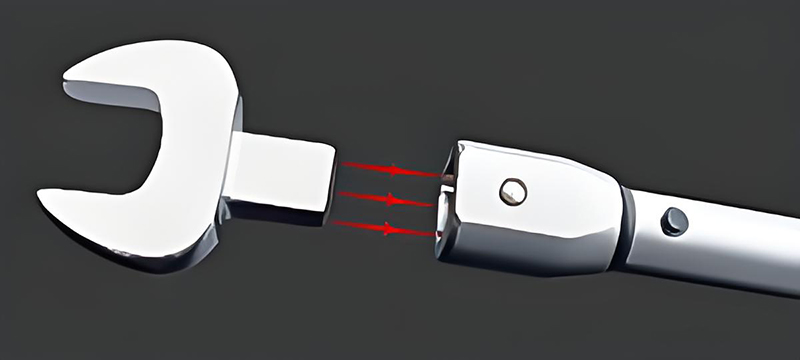

Ensure that the opening size of the selected wrench matches the size of the bolt or nut to avoid slippage and damage caused by size discrepancies.

To prevent damage and slippage of the wrench, the tension should be applied to the thicker side of the opening.

A torque wrench is designed based on the strength of human hands. When encountering tight threaded parts, the wrench cannot be hit with a hammer.

Except for socket wrenches, other types of wrenches cannot be equipped with force rods to prevent damage to the wrench or threaded connections.

When using a torque wrench, hearing a "click" indicates that the suitable torque has been reached.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

hk53tq]byxtccx]u71)vn.png)

Add: Yiqiao Town, Xiaoshan District, Hangzhou City, Zhejiang Province, China. 311256

Add: Yiqiao Town, Xiaoshan District, Hangzhou City, Zhejiang Province, China. 311256 Tel: +86-18072832111

Tel: +86-18072832111 E-mail:

E-mail: